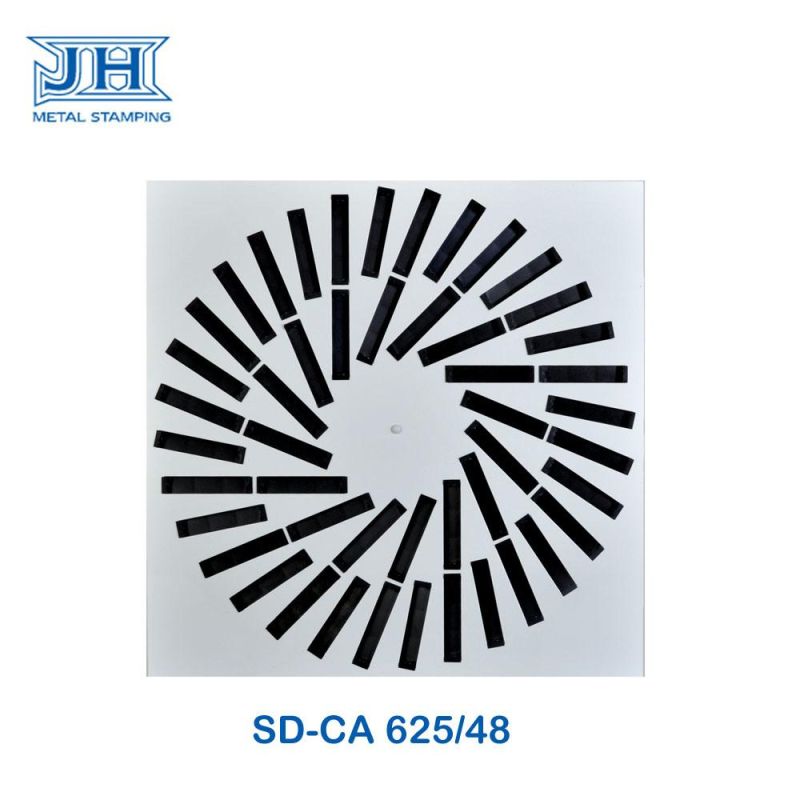

SPCC in Door Air Ceiling Diffuser

Ningbo Aier Ventilation Equipment Co., Ltd.- Certificate:SGS, ISO 9001

- Sample:Any Trial Order Is Welcomed

- Application:Air Supply or Exhaust in Ventilation System

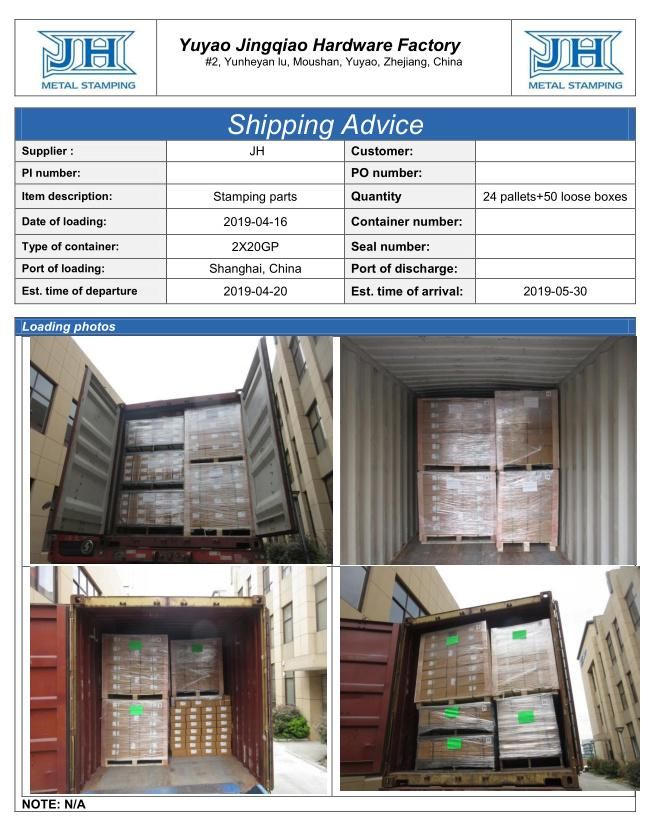

- Transport Package:Carton Case + Pallet

- Specification:Material: SPCC steel with white painting

- Trademark:JH

Base Info

- Origin:Ningbo, Zhejiang, China

- HS Code:7326909000

- Production Capacity:5000 PCS,Day

Description

2. Established in year 1997, with abundant experiences in manufacturing and exporting, quality guaranteed

3. Factory visit welcome

4. With in-house mold tooling workshop, all sorts of HVAC accessories and stamping parts can be manufactured according to customer's requirement, drawing, design or samples(OEM)

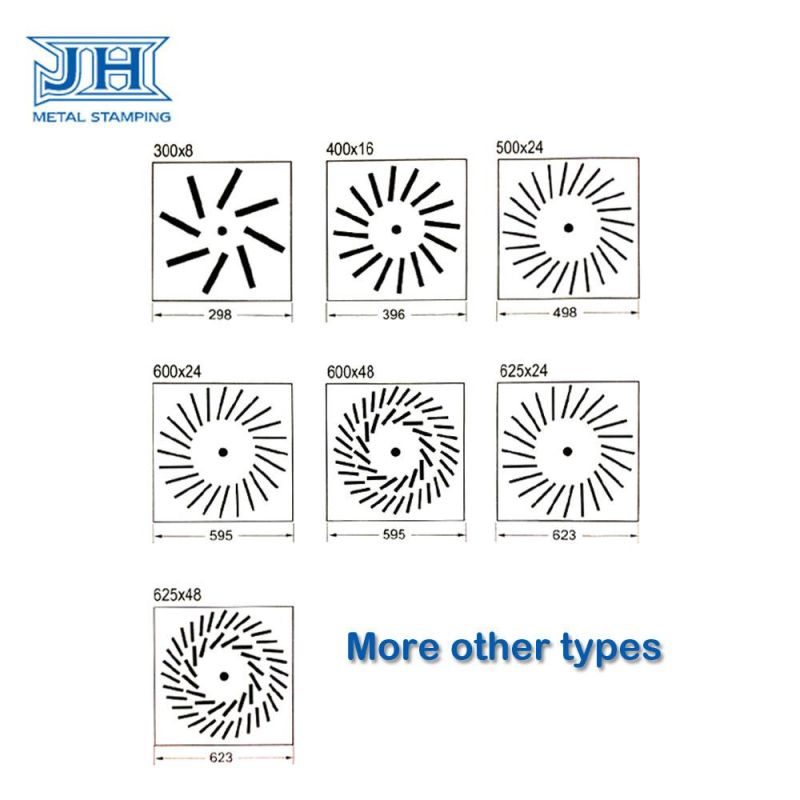

Other Available size

- Hydraulic plate shears

- CNC bending machine

- Hydraulic drawbench

- CNC laser cutting

- Robtic welder

- Automatic powder coating line

· Tapping

· Welding

· Drilling

· Assembly

· Painting

· Powder Coating

· Torque tester

· Tension machine

· Salt spray tester

· Zinc-coated tester

· Infrared ray tester

· Go and no go gauge

. Jigs.

Q: What is the payment method?

A: We accept TT (Bank Transfer), L/C.

1. For total amount under US$3000, 100% in advance.

2. For total amount above US$3000, 30% in advance, the rest against the copy document.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to

meet customers' requirement by adjusting our workshop schedule. Usually our normal lead time is 25-30

days for 1 full container; it is also up to the actual production situation and products structure.

Q: If you make poor quality goods,will you refund our fund?

A: We make products according to drawings or samples strictly until them reach your 100% satisfaction.

And actually we won't take a chance to do poor quality products.We are proud of keeping the spirit of

good quality.

Q: Could you offer competitive tooling cost?

A: We have own mold work-shop in our factory, for competitive tooling cost and on-time

samples.