Professional OEM Laser Cutting Black Power Coating Stamping Refrigeration Part

Ningbo Aier Ventilation Equipment Co., Ltd.- Type:Metal Stamping Parts

- Processing Type:Stamping Process

- Material:Q235B Metal

- Mould:Multistep Progressive Dies

- Surface Treatment:Power Coating

- Sample:Base on Inquire

Base Info

- Model NO.:JH002

- Certificate:SGS, ISO 9001,Ce

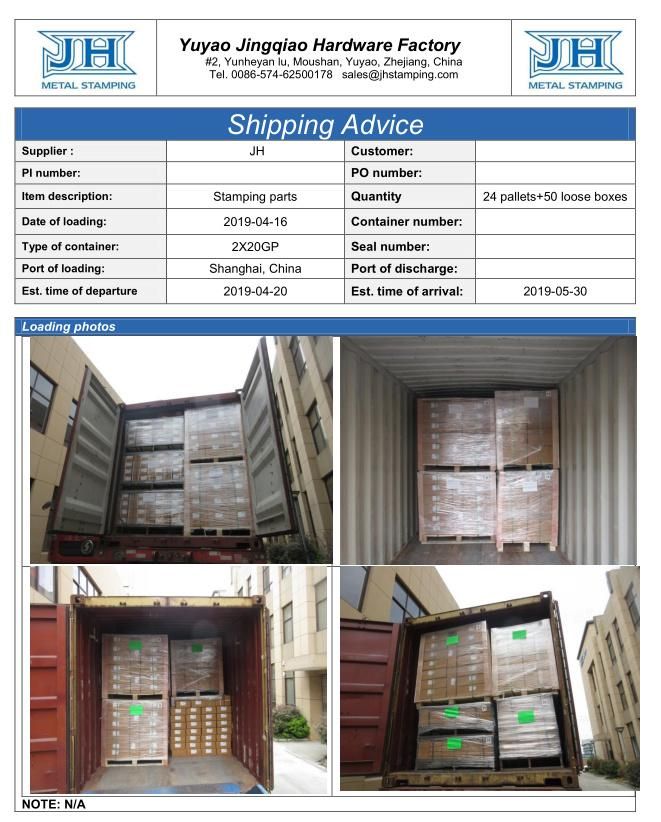

- Transport Package:Carton Case + Pallet

- Specification:custom

- Trademark:JH

- Origin:Ningbo, Zhejiang, China

- HS Code:7326909000

- Production Capacity:5000 PCS,Day

Description

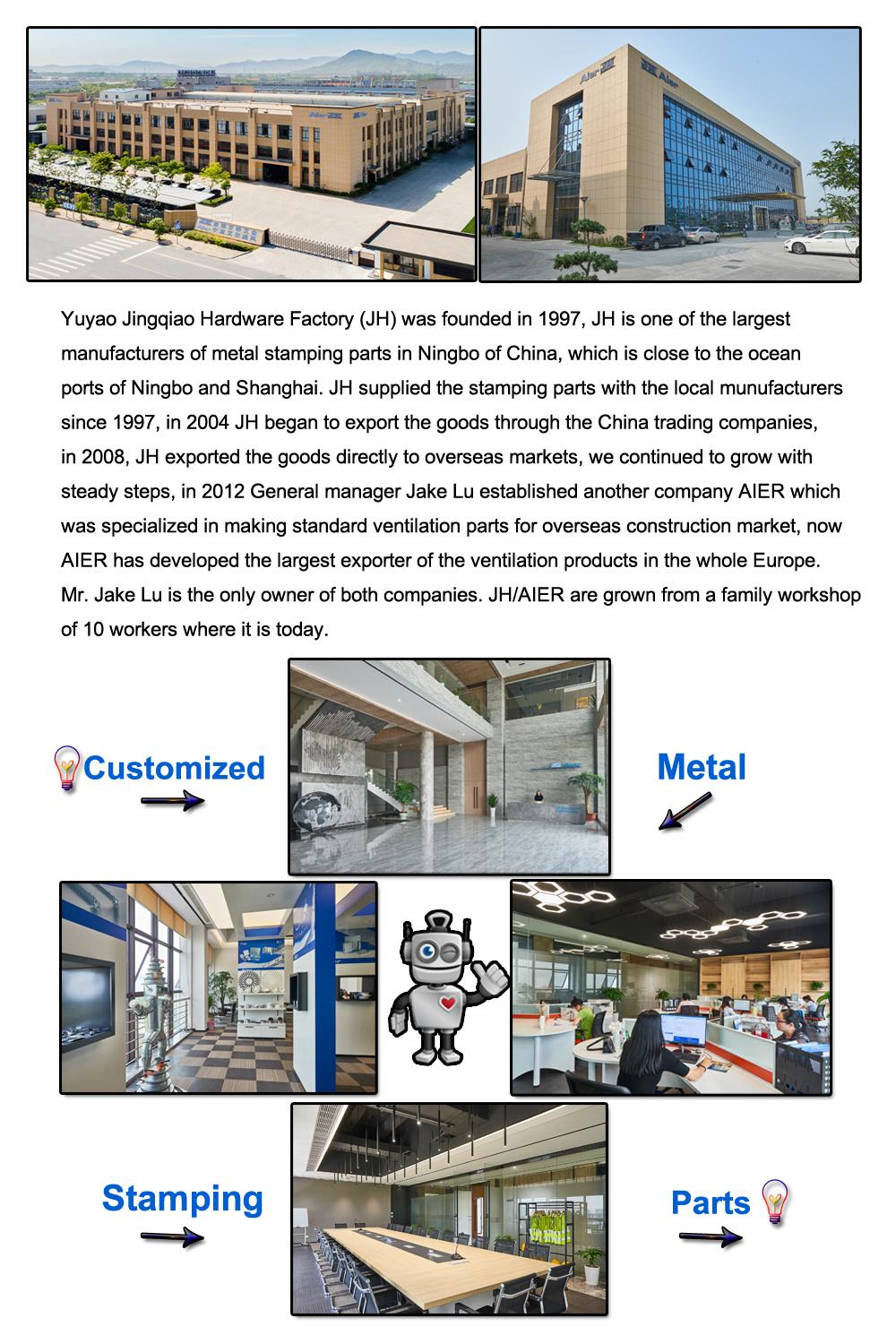

2. Had 20 years experience for manufacturing, exporting, and quality guaranteed.

3. Factory visit welcome.

4. With independent open mold capacity, all sorts of stamping parts can be manufactured according to customer's requirement, drawing, design or samples (OEM).

- Hydraulic plate shears

- CNC bending machine

- Hydraulic drawbench

- CNC laser cutting

- Robtic welder

- Automatic powder coating line

· Tapping

· Welding

· Drilling

· Assembly

· Painting

· Powder Coating

· Torque tester

· Tension machine

· Salt spray tester

· Zinc-coated tester

· Infrared ray tester

· Go and no go gauge

. Jigs.

Q: What is the payment method?

A: We accept TT (Bank Transfer), L/C.

1. For total amount under US$3000, 100% in advance.

2. For total amount above US$3000, 30% in advance, the rest against the copy document.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to

meet customers' requirement by adjusting our workshop schedule. Usually our normal lead time is 25-30

days for 1 full container; it is also up to the actual production situation and products structure.

Q: If you make poor quality goods,will you refund our fund?

A: We make products according to drawings or samples strictly until them reach your 100% satisfaction.

And actually we won't take a chance to do poor quality products.We are proud of keeping the spirit of

good quality.

Q: Could you offer competitive tooling cost?

A: We have own mold work-shop in our factory, for competitive tooling cost and on-time

samples.

If you are interested in product,please click " SEND " for more details. ↓↓↓