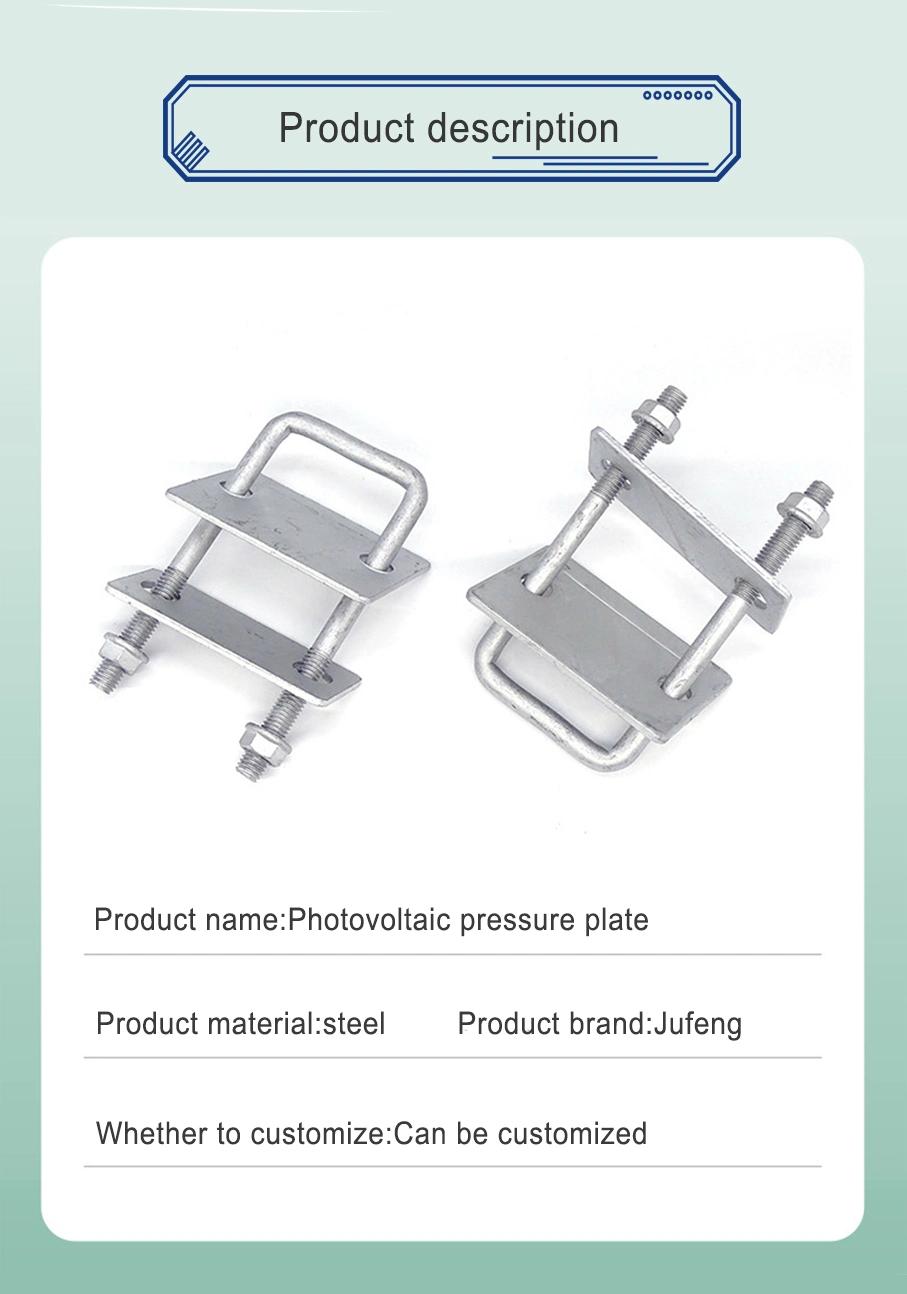

OEM New Energy/ Solar Panel PV System Mounting Structure Clamps

Weifang Jufeng Metal Products Co., Ltd.- Material:Stainless Steel

- Usage:Pipe Clamp

- Structure:Suspension Clamp

- Standard:Standard, Nonstandard

- Condition:New

- Brand:OEM

Base Info

- Model NO.:WF-JF

- Item:Pipe Clamp Clip

- Export Markets:Global

- Shipping Port:Qingdao

- Place of Origin:China

- Transport:by Sea

- Packing:Wooden Cases or Carton or Pallet

- Surface Treatment:Polishing,Galvanized,Electroplating

- Service:OEM and Customized

- Custom Made:Yes

- Logo Printing:Custonized

- MOQ:10-100PCS

- Free Sample:Yes

- Certificate of Origin:as Per Request

- Processing:as Per Your Drawing

- Weight:Customized

- Transport Package:Plywood Box

- Specification:SGS

- Trademark:OEM

- Origin:Weifang City, Shandong Province, China

- HS Code:7326199000

- Production Capacity:10000PCS,Month

Description

Basic Info.

Model NO. WF-JF Item Pipe Clamp Clip Export Markets Global Shipping Port Qingdao Place of Origin China Transport by Sea Packing Wooden Cases or Carton or Pallet Surface Treatment Polishing/Galvanized/Electroplating Service OEM and Customized Custom Made Yes Logo Printing Custonized MOQ 10-100PCS Free Sample Yes Certificate of Origin as Per Request Processing as Per Your Drawing Weight Customized Transport Package Plywood Box Specification SGS Trademark OEM Origin Weifang City, Shandong Province, China HS Code 7326199000 Production Capacity 10000PCS/MonthProduct Description

OEM Aluminum Solar mounting System Clamp Adjustable PV/ Photovoltaic Modules Clamps

Quick Details Place of Origin:Jiangsu, China Brand Name:TitanSolarModel Number:TT-IC-01 Wind Load:40m/s

Snow Load:70KN Warranty:10

Material:Aluminum 6005-T5 Surface Treatment:Aluminum Andized AA10-15

Tilt Angle:0-60 Degree Certificate:ISO9001 2022

Solar panel:Polycrystalline Silicon; Wind Speed:40m/s

Feature:Easy Install Foundation:Screw Pile

Component:Rail Connector Style:Solar Panel Mount Racking

OUR PRODUCING PROCESS:

1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

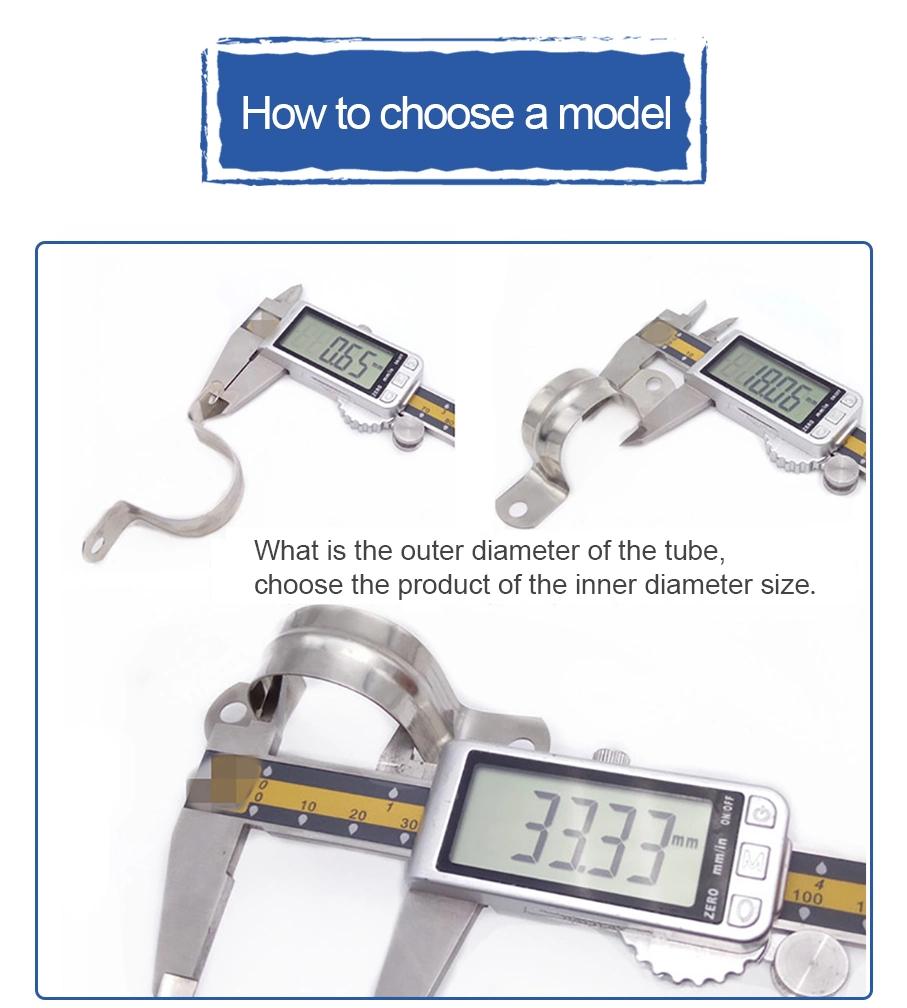

4. After finish manufacture process we will test the parts by the Image measurement instrument,

Caliper, Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface

treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the

parts which we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

Advantages:

Advantages:1. We are ODM&OEM, design according to your drawing.

2. Rich experience and good technology support.

3. Manufacturer and Trade Company.

4. Low MOQ is accepted.

5. 100% inspection before delivery.

6. Competitive price with high quality.

7. Convenient transportation ( Qingdao).

| Product type: | Hose Pipe Clamp |

| Material: | Stainless steel, iron, aluminum |

| Surface treatment: | brush finish, oxidation, screen printing, laser, sand blasting, galvanized |

| Color: | Black,Red,Yellow,Blue,Pink,Natural color |

| Precision tolerance: | +/- 0.1 |

| A. Raw Material | Copper ,BeCu, phosphor copper, Brass, Stainless steel, Aluminum, SGCC, SECC, steel, spring steel, Nickel-Silver... and all different kinds of metal; |

| B. SPEC | Roll material thickness is 0.05-10mm;sheet metal thickness is 0.3-20mm; |

| C. Surface treatment | Gold / Silver /Tin / Nickel / Zinc / Chromium / Copper-plating / Laser etching/Screen printing/Phosphating (can pass salt spray testing with 160 hours)/Black coating / Painting/ Power coating /Electrophoresis / Passivating /Deburring / Polishing / Brush according to ROHS standard; |

| D. Application | All different kinds of telecom products, loom, furniture, and so on ; |

| E. Quotation | Please provide the Formal drawings (normally, with DWG/STP/PDF file ),and make note with material/QTY/surface treatment and any other requirements, we will provide you the quotation sheet in 48-72 hours; |

| F. Prototype & Mould | We make the prototypes or moulds according to the drawings that confirmed by both of us and customers! The lead time is depends on the structure and qty of parts, Normally, lead time for prototypes is 3-15 days; lead time for mould is 10-25 days; |

| G. Production | We will provide samples according to the drawings to customers for approval. Then arrange the production and confirm the delivery date according to the Purchase Order; Normally , the lead time for production is 5-30 days ,the structure of parts is different , the lead time will be different . |

| H. Package | Plastic bags; Preserving Box; Reel/tape package; Plastic tray; Wood box; Export carton and any other customized package according to the customers' requests. |

Quality First,Price Best,Service Foremost!

We assure you of our best services at all times !

If you are interested in product,please click " SEND " for more details.