Drop Forged Screw Bolt G2150 Dee Shackle

Qingdao Thinkwell Hardware & Machinery Co., Ltd.- Material:Carbon +Alloy Steel

- Usage:Industrial

- Color:Silver

- Condition:New

- Process:Drop Forged

- Surface:Hot DIP Galvanized

Base Info

- Model NO.:G2150 Shackle

- Product Authentification:ISO, Ce

- Quality:a

- Other:Customized

- Transport Package:Carton, Bag, Pallet

- Specification:CE, ISO

- Trademark:Thinkwell

- Origin:Qingdao, China

- HS Code:7326909000

- Production Capacity:2000PCS Per Day

Description

Basic Info.

Model NO. G2150 Shackle Product Authentification ISO, Ce Quality a Other Customized Transport Package Carton, Bag, Pallet Specification CE, ISO Trademark Thinkwell Origin Qingdao, China HS Code 7326909000 Production Capacity 2000PCS Per DayProduct Description

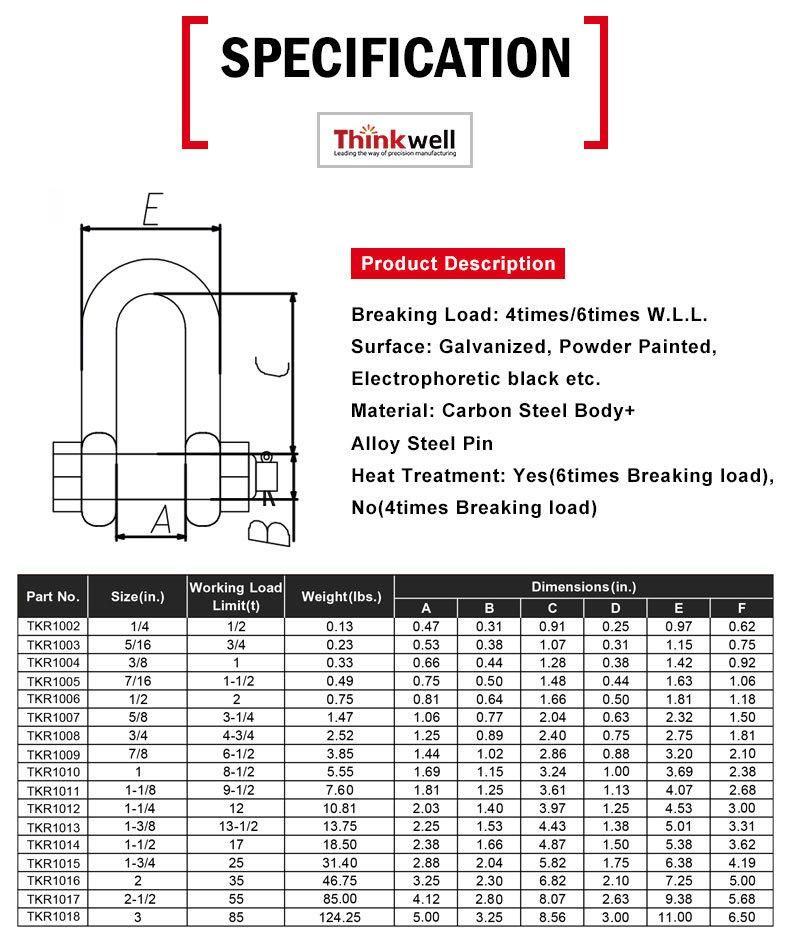

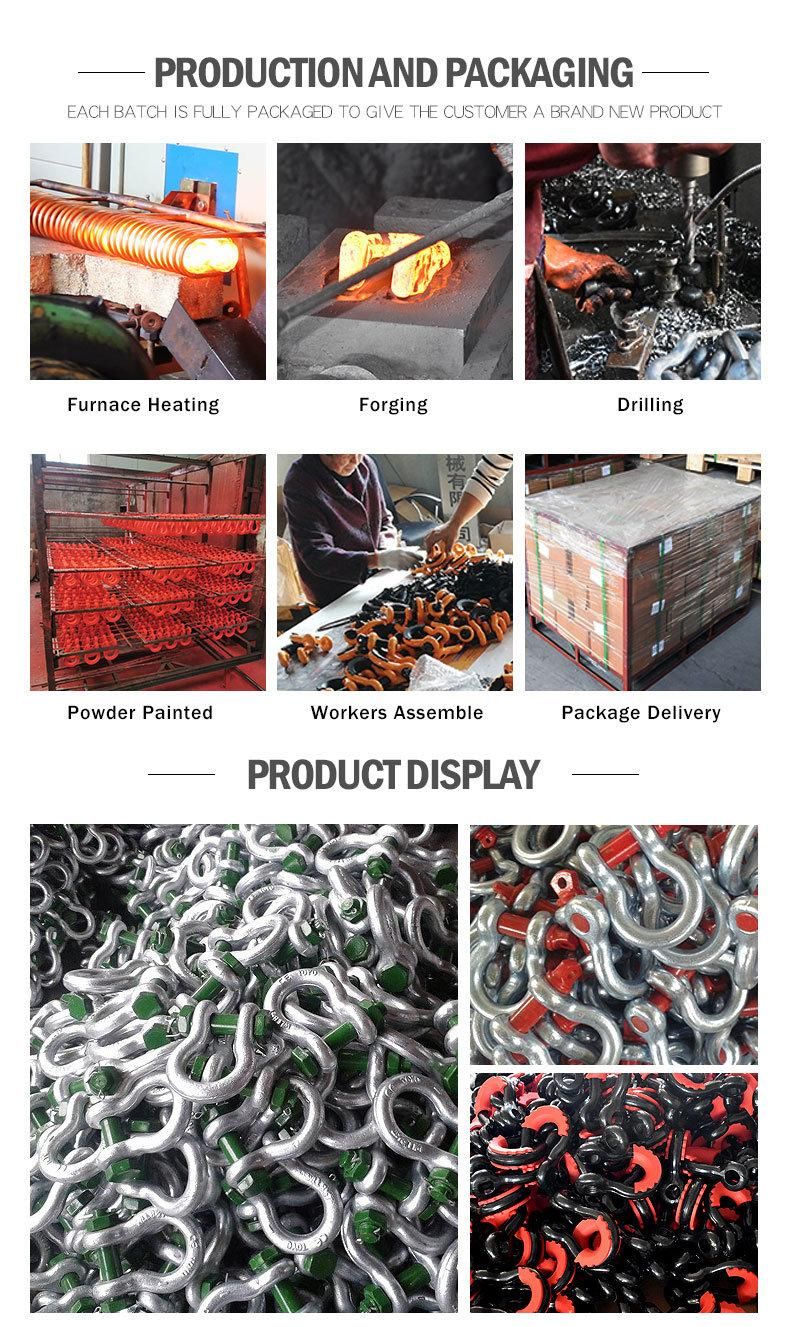

Drop Forged Screw Bolt G2150 Dee ShackleMaterial: Body with carbon steel 45#, Pin with 40cr

Treatment: Forging

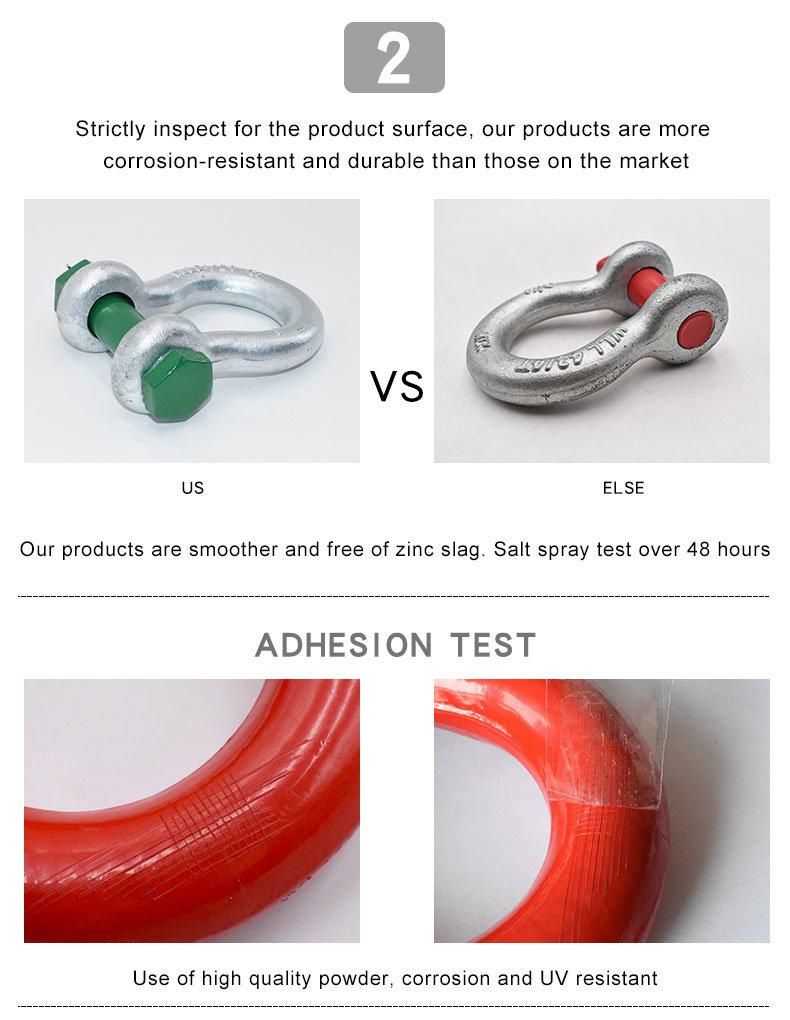

Finish: Hot DIP Galvanized, or as requested

Packing: Cartons or Gunny bags, Pallet

Origin: China

FOB Port: : Qingdao

Lead time: 15~45 Days

Main export market: US, Australia, European countries, India

Standard: CE, ISO

ISO 9001:2008 Certified Factory, Customized requirements are welcome!

Qingdao Thinkwell also manufactures hooks, shackles, turnbuckles, wire rope clips, load binders and other rigging hardware accessories.

Qingdao Thinkwell also manufactures hooks, shackles, turnbuckles, wire rope clips, load binders ,auto parts,electric powder fitting and other rigging hardware accessories.

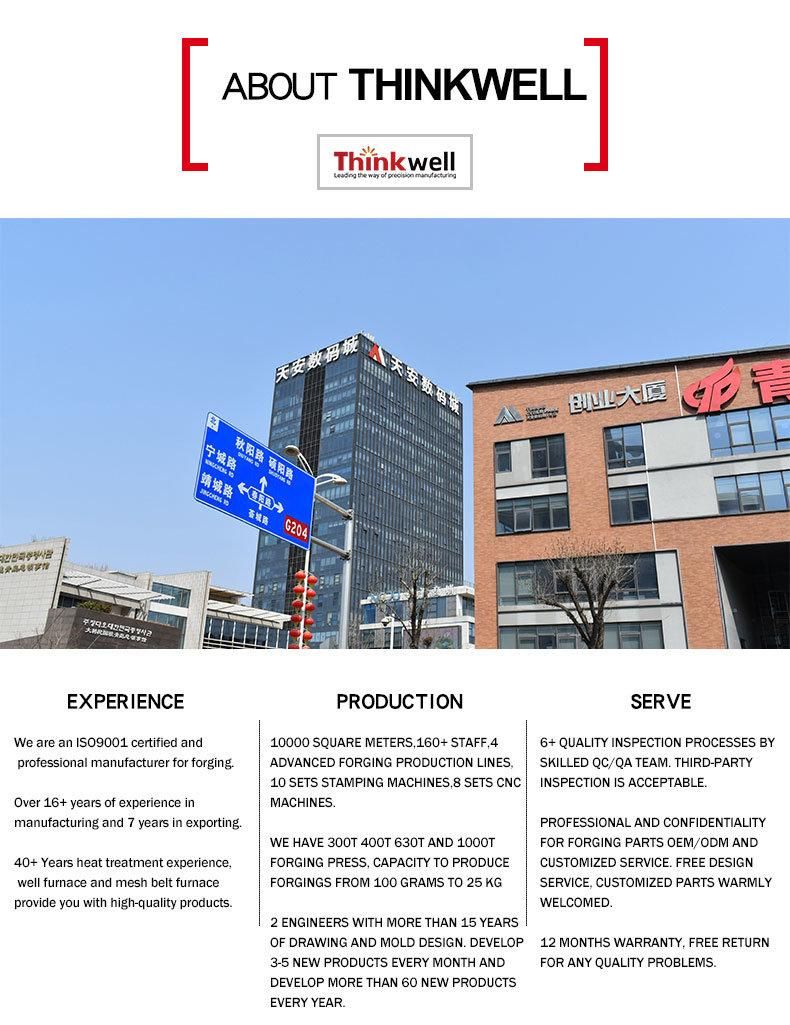

Qingdao Thinkwell Hardware & Machinery Co., Ltd is the manufacturer deals in Rigging Hardware, Forged Engine Connecting Rod and Automobile Forging Parts over 10years.

Our rigging hardware factory covers an area of 8, 000 square meters and its architectural area is 5, 000 square meters. It has over 100 staff, including 3 engineers, 10 specialized technican, owned advanced machinery and equipment.

Rigging Hardware Equipment:

1)1000 T forged pressing machine,

2)160T/300T/400T/630 T forged pressing machine,

3)2 production line, include a set of punch, thread rolling machine, tapping machines, lathes, milling machines.

In 2009, our company invest over five millions to our cooperate company and bulit two new advanced intermediate frequency induction heating, forging forming, heat quenching forging production lines to produce Automobile forging parts and Engine Connecting Rod. In April of 2010, get TS16949 international quality system certification. Our Auto forging parts and Connecting Enjoying good reputation in domestic and world market because of good quality and competitive price.

Main Equipment for Automobile Forging parts and Connecting Rod:

1)1600T/1000T/630T Forged Pressing Machine

2)800 kw intermediate frequency induction furnace

Qingdao Thinkwell also manufactures hooks, shackles, turnbuckles, wire rope clips, load binders ,auto parts,electric powder fitting and other rigging hardware accessories.

Qingdao Thinkwell Hardware & Machinery Co., Ltd is the manufacturer deals in Rigging Hardware, Forged Engine Connecting Rod and Automobile Forging Parts over 10years.

Our rigging hardware factory covers an area of 8, 000 square meters and its architectural area is 5, 000 square meters. It has over 100 staff, including 3 engineers, 10 specialized technican, owned advanced machinery and equipment.

Rigging Hardware Equipment:

1)1000 T forged pressing machine,

2)160T/300T/400T/630 T forged pressing machine,

3)2 production line, include a set of punch, thread rolling machine, tapping machines, lathes, milling machines.

In 2009, our company invest over five millions to our cooperate company and bulit two new advanced intermediate frequency induction heating, forging forming, heat quenching forging production lines to produce Automobile forging parts and Engine Connecting Rod. In April of 2010, get TS16949 international quality system certification. Our Auto forging parts and Connecting Enjoying good reputation in domestic and world market because of good quality and competitive price.

Main Equipment for Automobile Forging parts and Connecting Rod:

1)1600T/1000T/630T Forged Pressing Machine

2)800 kw intermediate frequency induction furnace

3)The pusher-type continuous tempering furnace

Rigging Hardware Products: Load Binders, Turnbuckles, Shackles, Hooks, Wire Rope Clip, Wire Rope Thimbles, Eye Bolts&Nuts, Connecting Links, Anchor, Chain Accessories...etc.

Automobile Forging Products:

1. Automobile, engineering machinery forging parts.

2. Automobile steering arm, rack forging parts

3. Automobile, engineering machinery engine connecting rod assembly

"Our Service, Your Safety", "Customers Demand, Our Pursuit ". To provide the most suitable products and pragmatic services is our firm belief. We can design and manufacture varies of products according to customers requirements. We have been putting the priority to the QUALITY, SINCERITY, EFFICIENCY, and SERVICE.

Sincerely wish long-term cooperation between you and us. Warmly welcome to our company for a visit.

FQA:

Are you a factory or a trading company?

1. We are a factory focused on the rigging hardware, auto parts, forged parts over 10 years.

2. Our products are shackles, turnbuckles, hooks, chains, load binders, bolts&nuts, wire rope clips, thimbles, connecting rods etc.

3. We own advanced equirpments and 2 production lines like 1000t, 630t, 400t , 300t, 160t forged presing machine, purch, thread rolling machine, tapping and milling machine.

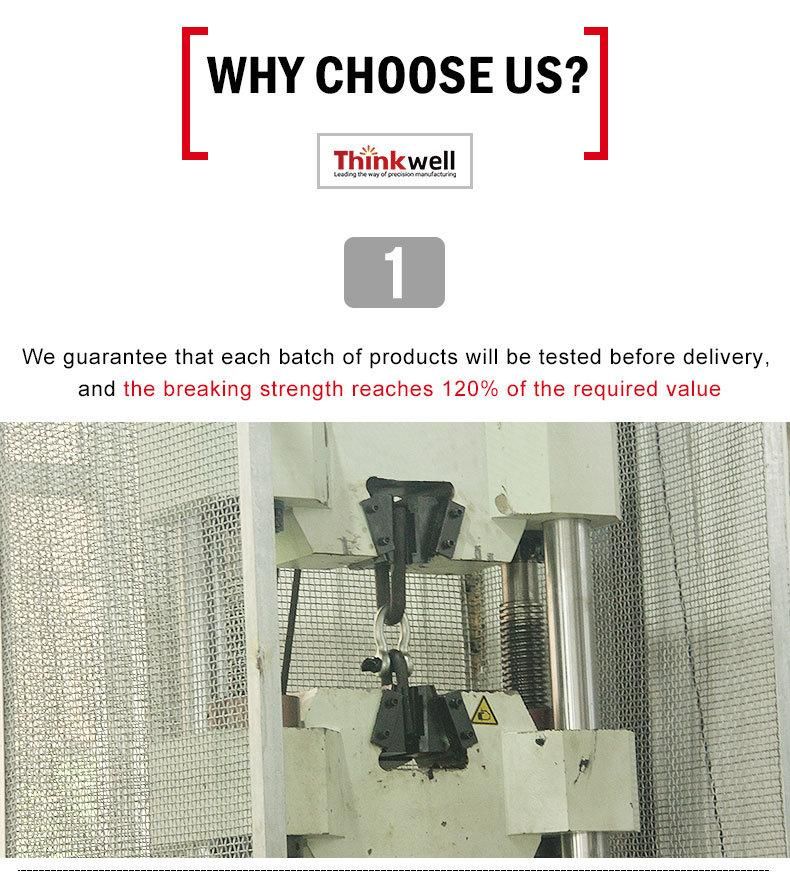

What is your Quanlity Guarantee?

1. High quanlity steel material from famous stel group.

2. All of the products was qualifled before shipping.

3. The third party product inspections are acceptable.

How can I get a smple to check your quality?

Required Samples will be sent after price confimation. If place order, freight will be returned back.

Why I choose you?

1. Rich expenience on rigging hardware over 10 yuears.

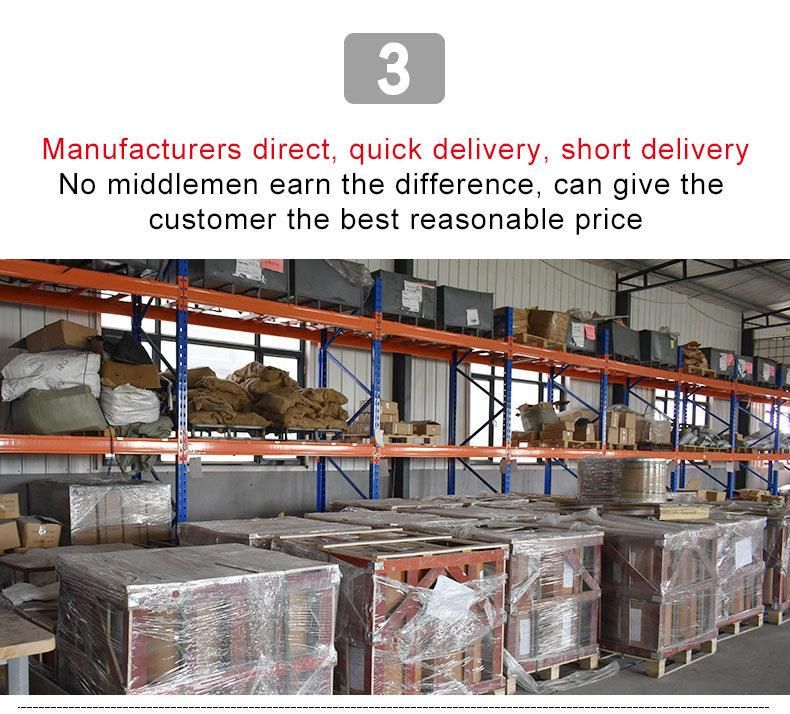

2. Delivery time is 15-45 days.

3. ISO, SGS Certification.

4. Over 100 staff, inducting 3 engineers, 10 speciaized technican.

Please feel free to contact me for more information!