21.7 Ton Tensile Force Forged Weld G80 Master Link Sub Assembly Rigging Hardware

Weifang First Rigging Co., Ltd.- Process:Heat Treatment+Surface Treatment

- Certificate:ISO9001

- Scale:1-1,2 Inch (21.7 Ton)

- Size:35mm*267mm*133mm-28mm*180mm*100mm

- Weight:12.6 Kg ,PCS

- MOQ:1 Ton

Base Info

- Surface Treatment:Plastic Spraying

- Transport Package:According to Your Requirements

- Specification:piece

- Trademark:First Rigging

- Origin:China

- HS Code:73261910

- Production Capacity:30ton,Month

Description

Basic Info.

Surface Treatment Plastic Spraying Transport Package According to Your Requirements Specification piece Trademark First Rigging Origin China HS Code 73261910 Production Capacity 30ton/MonthProduct Description

Plastic spraying Master Link Assembly:

Own factory of us, many years of experience in Round Master Link Assebmly production, good quality of conscience , supply to some large domestic customers, have a good reputation with low breakage rate, attracted some customers from other places for cooperation. In recent years, our Round Master Link has also attracted more and more foreign customers and continues to go to overseas markets.

Technical Specification:

Technical Specification:

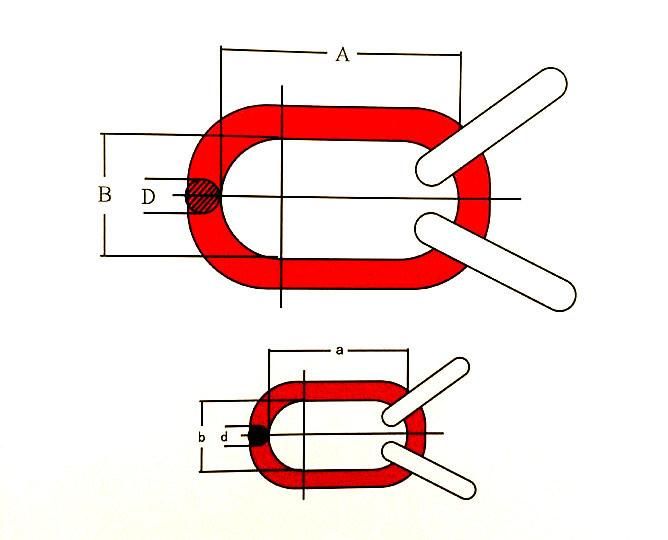

Size | A | B | D | a | b | d | WLL(Ton) | Weight(Kg) |

1-1/2 | 267 | 133 | 35 | 180 | 100 | 28 | 21.7 | 12.6 |

Features :

True mold forging, the choice of confidence quality:

1.High strength and high toughness special alloy steel is selected, through process of heat treated.

2.The verification test is gradually performed at 2.5 times of working tension.

3.Strict sample breaking test and fatigue test for each batch of product

4.Broken tension is 4 times of the working tension

Use method show of Master Link Assembly with other Lifting sling hardware :

Warning: Never exceed the working load limit to use

Packaging & Delivery:

Packing details: Usually packed in plastic bags, and then in export carton, high quality pallets

Delivery Detail: Usually 30-40 working days after receiving your advance payment.

Customer show :

Certificate :

FAQ :

1. Where is your factory located?

In Changle, near Qingdao city, about 2 hours by car.

Welcome to Visit.

2. What products do you supply?

1) Lifting link chain, Coal Mining chain

2) Round Master link

3) Other related products

3. How do I pay?

TT(Telegraphic Transfer),30% payment in advance, 70% balance before shippment .

4. How do I receive the goods ?

FOB, C&F, CIF are most commonly used trade terms.