SUN-MAX STEEL CO., LIMITED

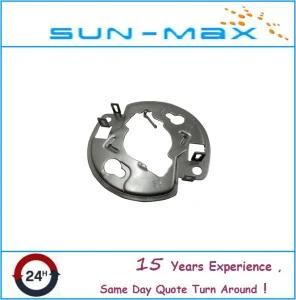

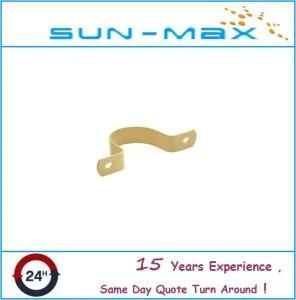

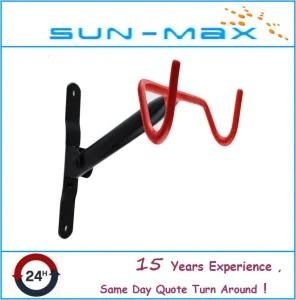

SUN-MAX have extensive experience in the manufacturing and exporting of non-standard fasteners, special hardware components and metal parts for the automotive, medical care, consumer electrical, aerospace and precision instruments etc., working with both small and large customers across the world over the past 15 years, making us best placed to help with your inquiry.

Whether you are looking for a few hundred non-standard fasteners or huge quantity speciality hardware components, we value the specific and diverse needs of our customers. If you have an inquiry please send us email or call us.

Products:

According to customer drawing or sample, develop precision tools, dies and moulds, manufacture to your specifications exactly in just weeks! Materials can be Stainless Steel, Carbon Steel, Steel Alloy, Aluminum Alloy, Brass, Copper and Engineering Plastics etc.,

Material Available:

1. Stainless steel: SS202, SS303, SS304, SS316, SUS420J2 etc.,

2. Mild Steel / Carbon steel: Q195, Q235, Q295, Q345, 1010, 1020, 1035, 1045, etc

3. Brass / Copper: C11000, C10200, C12000, C21000, C27000, C36000, C38000, etc

4. Aluminum or Aluminum Alloy: 1050, 1060, 5052, 6061, 6063, 5056, etc

5. Alloy Steel: 1024, 1340, 6150, 4140, 4135, 10B21, 35ACR, 40ACR, 40Cr, 35CrMn, etc

Stainless Steel

SS202, SS301, SS302, SS304, SS316, SS416, SS430, etc.

Mild Steel / Carbon steel

Q195, Q235, Q295, Q345, 1010, 1020, 1035, 1045, etc.

Brass / Copper

C11000, C10200, C12000, C21000, C27000, C36000, etc.

Aluminum

1050, 1060, 5052, 6061, 6063, 5056, etc.

Alloy Steel

1024, 1340, 6150, 4140, 4135, etc.

Surface finish:

Gringding, Zinc, nickel, chrome, passivate, anodizing, plastic spraying, powder coating, etc.,

Heat treating:

Case hardening, annealing, Normalizing, Hardening, Tempering, Nitridation, Carburization, etc.,

Assembly:

Custom assembly available upon request

Quality Control:

We setup total management quality systems following ISO9001, from the IQC to IPQC to OQC, strictly execute customer quality requirement, to achieve quality target.

We owns advanced quality control and inspection facilities, is capable to perform mechanical property, dimension & contour and corrosion-resistance test at the incoming, in-process, and outgoing stages

Testing Equipment:

CMM, Projector, Pull Tester, Automatic Optic Inspector, Projecting apparatusSalt Spray Test,

Durometer, and Coating Analyzer, Tensile Machine

Shipment

By air: Airport to Airport

By sea: FOB Shanghai or Ningbo, CIF, DDU, DDP

Package:

Nylon bags, cardboard cartons, Iron bucket, wooden case, wooden crate, or as per your requests

Warranty

Replacement at all our cost for rejected products

Equipment& Facilities

We are equipped with more than 150 equipments and faciities, including 1000T, 400T, 300T press machine/friction press, 200T, 125T, 100T, 63T hydraulic sheet metal drawing presses, Polishing equipments, welding robot and others like CNC Lathes, milling machines, facing machines, drilling machines, injection molding machines and etc.,

Contact us now - Let′s get started!

SUN-MAX STEEL Co., Limited.

No. 55 Yuli Road, Yuyao City Zhejiang Province, China.

Contact Person: Wendy Hu

Tel: 0086 574 62732890

Fax: 0086 574 22677733

MB: 0086 13385847618

Email: Nbhcw@VIP. 126. COM

Sunmax@VIP. 126. COM

Whether you are looking for a few hundred non-standard fasteners or huge quantity speciality hardware components, we value the specific and diverse needs of our customers. If you have an inquiry please send us email or call us.

Products:

According to customer drawing or sample, develop precision tools, dies and moulds, manufacture to your specifications exactly in just weeks! Materials can be Stainless Steel, Carbon Steel, Steel Alloy, Aluminum Alloy, Brass, Copper and Engineering Plastics etc.,

Material Available:

1. Stainless steel: SS202, SS303, SS304, SS316, SUS420J2 etc.,

2. Mild Steel / Carbon steel: Q195, Q235, Q295, Q345, 1010, 1020, 1035, 1045, etc

3. Brass / Copper: C11000, C10200, C12000, C21000, C27000, C36000, C38000, etc

4. Aluminum or Aluminum Alloy: 1050, 1060, 5052, 6061, 6063, 5056, etc

5. Alloy Steel: 1024, 1340, 6150, 4140, 4135, 10B21, 35ACR, 40ACR, 40Cr, 35CrMn, etc

Stainless Steel

SS202, SS301, SS302, SS304, SS316, SS416, SS430, etc.

Mild Steel / Carbon steel

Q195, Q235, Q295, Q345, 1010, 1020, 1035, 1045, etc.

Brass / Copper

C11000, C10200, C12000, C21000, C27000, C36000, etc.

Aluminum

1050, 1060, 5052, 6061, 6063, 5056, etc.

Alloy Steel

1024, 1340, 6150, 4140, 4135, etc.

Surface finish:

Gringding, Zinc, nickel, chrome, passivate, anodizing, plastic spraying, powder coating, etc.,

Heat treating:

Case hardening, annealing, Normalizing, Hardening, Tempering, Nitridation, Carburization, etc.,

Assembly:

Custom assembly available upon request

Quality Control:

We setup total management quality systems following ISO9001, from the IQC to IPQC to OQC, strictly execute customer quality requirement, to achieve quality target.

We owns advanced quality control and inspection facilities, is capable to perform mechanical property, dimension & contour and corrosion-resistance test at the incoming, in-process, and outgoing stages

Testing Equipment:

CMM, Projector, Pull Tester, Automatic Optic Inspector, Projecting apparatusSalt Spray Test,

Durometer, and Coating Analyzer, Tensile Machine

Shipment

By air: Airport to Airport

By sea: FOB Shanghai or Ningbo, CIF, DDU, DDP

Package:

Nylon bags, cardboard cartons, Iron bucket, wooden case, wooden crate, or as per your requests

Warranty

Replacement at all our cost for rejected products

Equipment& Facilities

We are equipped with more than 150 equipments and faciities, including 1000T, 400T, 300T press machine/friction press, 200T, 125T, 100T, 63T hydraulic sheet metal drawing presses, Polishing equipments, welding robot and others like CNC Lathes, milling machines, facing machines, drilling machines, injection molding machines and etc.,

Contact us now - Let′s get started!

SUN-MAX STEEL Co., Limited.

No. 55 Yuli Road, Yuyao City Zhejiang Province, China.

Contact Person: Wendy Hu

Tel: 0086 574 62732890

Fax: 0086 574 22677733

MB: 0086 13385847618

Email: Nbhcw@VIP. 126. COM

Sunmax@VIP. 126. COM

Product List